Industries & Projects

Photo Courtesy of Enviva

Many industries employ operations and processes that carry an inherent risk of fire. In facilities that handle combustible dusts, this risk can be far greater as the generation of a single spark could have dire consequences. The flexibility of the FLAMEX System allows it to be designed to address various fire and explosion hazards present in these facilities.

The wide variety of detection options and desired outputs that are available make the FLAMEX System an ideal solution to meet the protection requirements found in a number of industrial applications. The following are examples of industries in which FLAMEX Systems have been and are being successfully utilized to prevent and combat the consequences of dangerous fires and explosions.

Woodworking

The fine dust produced in the manufacturing of wood products can be highly explosible. The abrasive nature and friction associated with these processes in woodworking facilities such as sanding, planing, routing, trimming of wood products, which produce fine dust, are also conducive to spark generation, which is the potential ignition source for dust fires. Size reduction operations such as hogging and hammermilling of wood waste material and the collection of the dust particulate resulting from the manufacturing processes also pose dangerous hazards. Furniture, Cabinet, Lumber, Flooring, Store Fixtures and Millwork are all examples of secondary woodworking products that are produced in facilities where these risks commonly exist.

Composite Board facilities utilize many of these same processes in addition to the drying of green wood material and the formation of the wood composite board in the pressing operation. The high heat from rotary dryers can sometimes produce overheated material and sparks which will be conveyed downstream to cyclones and process areas. The Board Press (whether it be a continuous press or a multi opening press) creates an especially risky environment as it brings together a potentially flammable mixture of elements such as dry wood fiber, heat, bonding agents, hydraulic and thermal oils and expose this mix to the possibility of ignition through mechanical friction sources.

The manufacturing of wood pellets also pose similar risks associated with the drying and size reduction processes in addition to unique hazards posed in the pelletizing and cooling of hot wood pellets.

Recycling

Size reduction operations required to recycle rubber tires, electronic waste, municipal solid wastes and other materials are often conducive to the generation of sparks and fire. High speed machinery used to shred, grind or granulate combustible material to a desired size specification may create the heat or friction sparks for ignition.

Food

The processing of food products may involve drying and roasting, milling, grinding and other size reduction processes, pneumatic conveying of combustible materials as well as the air filtration of waste stream materials. Protection applications exist in the production and processing of coffee, spices, milk powder, cereal, sugar, tea and many other food products.

Paper

Cellulosic fibers found in various forms such as paper, cardboard and tissue are easily ignitable.

Industrial facilities that manufacture paper related products may employ trimming, bailing, and cutting operations in addition to scrap waste removal and dust collection systems.

Protection applications exist in plants involved in printing, packaging, corrugated, paper tube, tissue and hygiene products.

Metal

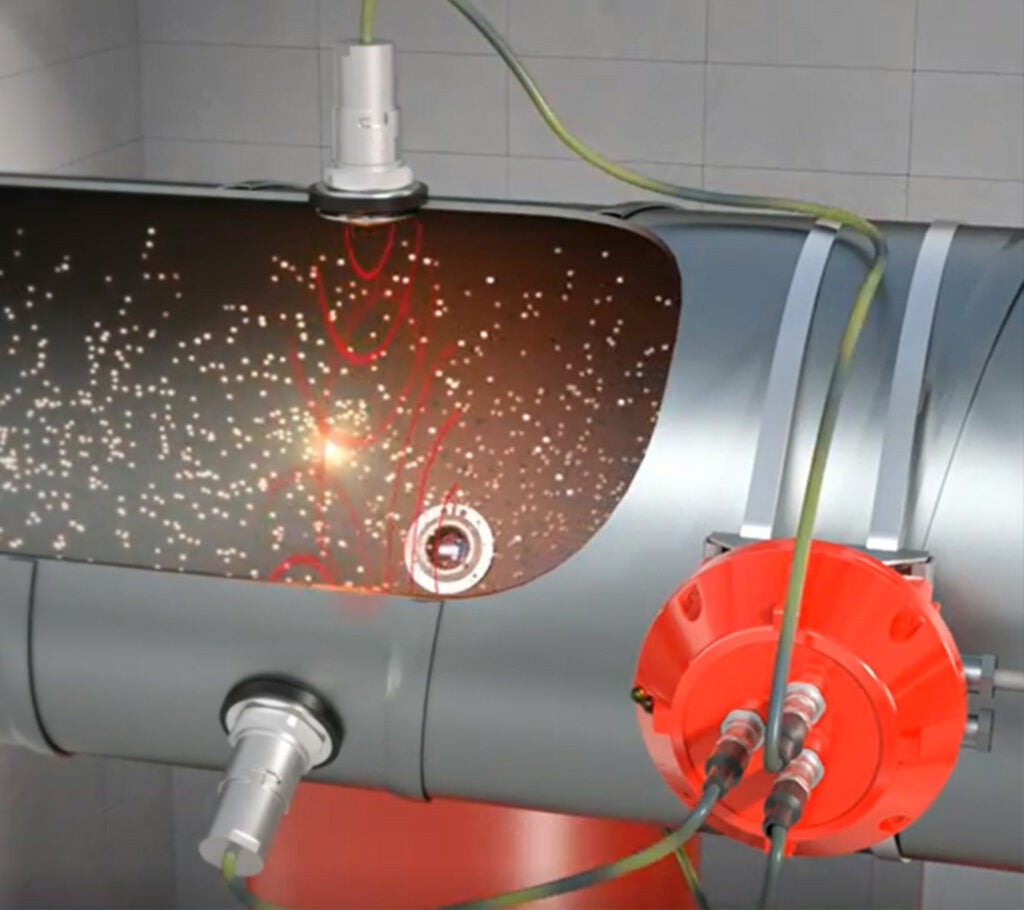

Although not often considered combustible by many, metal dust can burn and explode under the right conditions. Metalworking operations involving robotic welding, grinding, polishing and laser cutting can ignite fires often in dust collectors due to the spark producing nature of the abrasive operations and the methods used in cutting and welding.

Agricultural

The handling, drying, processing and storage of many agricultural products can present hazards in industrial facilities involved in these operations. Protection applications are found in the processing of grain, soybeans, alpha, almonds, peanuts and tobacco among others.

Other Industries

Protection applications also exists in numerous other industries not listed above including Automotive, Battery Manufacturing, Animal Feed, Plastics and Foundries.

FEATURED PROJECTS

MEDIUM DENSITY FIBERBOARD FACILITY, SOUTHEASTERN U.S.

FLAMEX PROTECTION INCLUDES:

- 48 Spark Detection Zones

- 17 Deluge Systems

- 3 Foam Deluge Systems

- Minfog Water Mist System with 450 Nozzles

- Project Supervision

OSB FACILITY, SOUTHEASTERN U.S.

FLAMEX PROTECTION INCLUDES:

- 81 Spark Detection Zones

- 2 Minifog Press Protection Systems

- Conveyor Protection Deluge System for 10 Conveyors

- 9 Control Panels Networked by Inveron HMI Fire Monitoring System

MEDIUM DENSITY FIBERBOARD FACILITY, BRITISH COLUMBIA

FLAMEX PROTECTION INCLUDES:

- 64 Spark detection Zones

- Deluge of Fiber Bins & Silos

- Minifog Water Mist System with 450 Nozzles for Continuous Press

- Control Panels Networked by Inveron HMI System

OSB FACILITY, SOUTHEASTERN U.S.

FLAMEX PROTECTION INCLUDES:

- 50 Spark Detection Zones

- Minifog Protection System for Conti-Roll Press

- Conveyor Protection Deluge System for 12 Conveyors

- Forming Line Protection System Including Deluge Systems for the Forming Bins and Forming Heads

- Blender Deluge Systems

- AFFF Foam Deluge Systems for Thermal and Hydraulic Rooms

- 4 Control Panels

- Inveron HMI Process Fire Protection Monitoring System

OSB FACILITY, SOUTHEASTERN U.S.

FLAMEX PROTECTION INCLUDES:

- 95 Spark Detection Zones

- Minifog Protection System for Multi-Opening Press

- Conveyor Protection Deluge Systems

- Forming Line Protection System Including Deluge Systems for the Forming Bins and Forming Heads

- Blender Deluge Systems

- AFFF Foam Deluge Systems for Press Pit

- 6 Control Panels

- Inveron HMI Process Fire Protection Monitoring System

LONGEST CONTINUOUS PARTICLEBOARD PRESS IN NORTH AMERICA

FLAMEX PROTECTION INCLUDES:

- 350 Spark Detectors & Test Lights

- 160 Automatic Flame, Heat & Smoke Detectors

- 138 Extinguishing Assemblies with Flat Spray Nozzle

- 3300 MINIFOG Spray Nozzles

- 8 Control Panels Networked by Inveron

- HMI Fire Monitoring System with 3 Work Stations

A FEW OF OUR VALUED CUSTOMERS

WHAT WE DO

SPARK DETECTION & SUPPRESSION SYSTEM

MINIFOG WATER MIST SYSTEM

COMPONENTS

MXONE

HOW CAN WE HELP

Contact our support team for project inquiries, technical questions and service.