Add Automatic Blast Gates

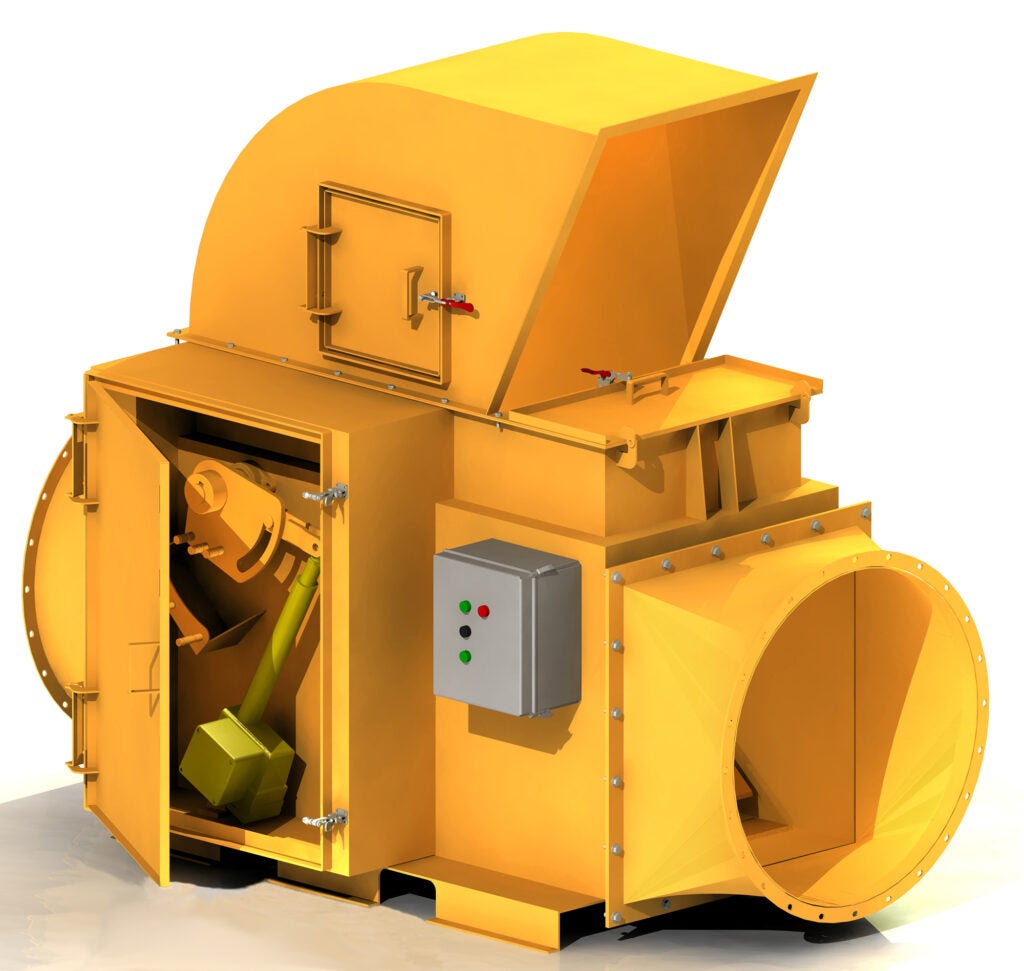

Abort Gate

An Abort Gate is a high-speed damper that contains a spring assisted blade held in place by an electromagnet. It diverts sparks, flames, burning material, smoke, and combustion gases out of the pneumatic system to a safe location.

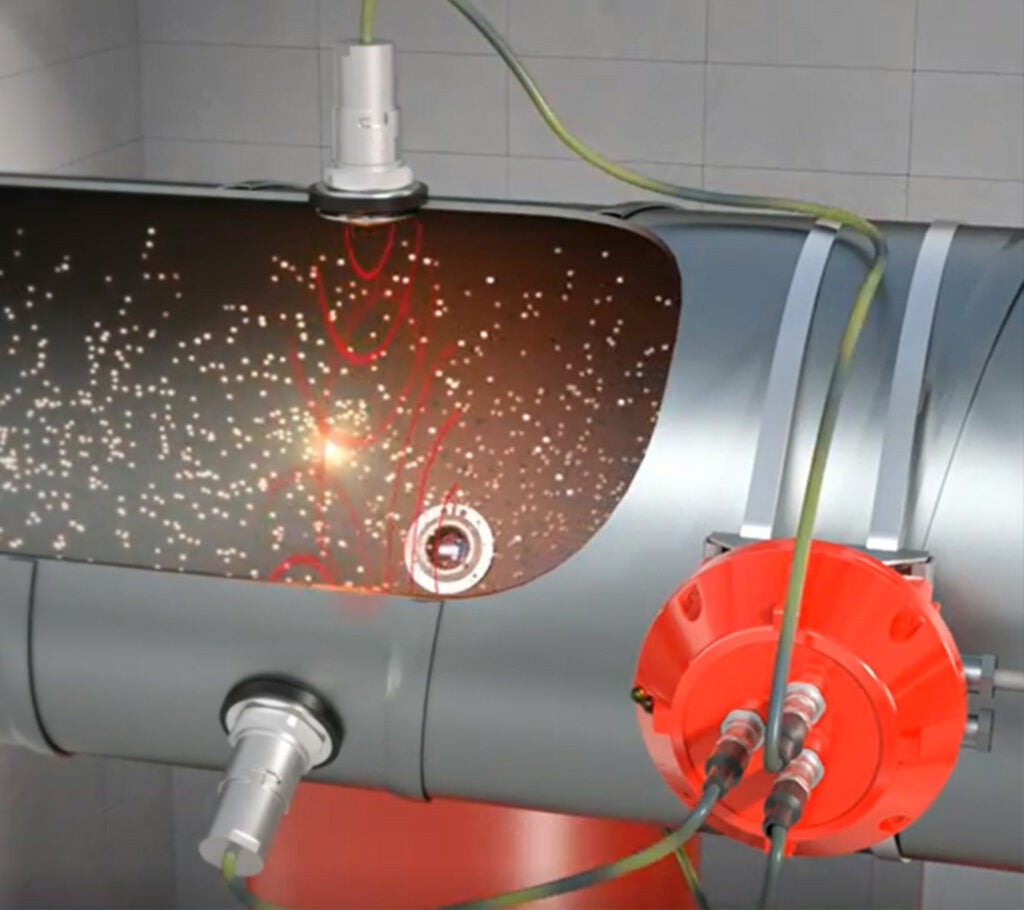

Abort Gates are activated by spark detectors mounted on the ductwork upstream of the unit. Upon detection of IR by the spark detector, the system diverts the air flow through the discharge hood of the abort gate to atmosphere. The reaction time will vary depending upon the diameter of the duct. However, most units will react within 1/2 second (500 milliseconds).

Abort Gates are typically installed in return air or clean air ducts recycling air back into the building from a dust collector. When applied in this manner, the abort gate serves to isolate the dust collector from the building in the event of a fire in the collector or when a spark is detected in upstream ductwork. It’s primary function is to protect the building and its occupants from harmful products of a dust collector fire (sparks, fire, burning material, smoke and pre-combustion gases). The abort gate purges the material from the return air duct to prevent entry into the plant.

Although the response time of the gate is very rapid (.5 seconds or less), there is no guarantee that an explosion or deflagration from the collector can be fully or partially vented to atmosphere. For this reason, the maximum length of spacing possible between the sensors and the abort gate in return air ducts should be utilized to increase the effectiveness of the abort function.

In some applications, abort gates can be located upstream of the dust collector in material handling ducts so they can be used to prevent any spark or burning ember from reaching the collector. In most cases, abort gates are installed downstream of the fan so that any ignition source in the air stream is purged from the pneumatic system.

A variety of options are available. This allows the user to customize the gate to meet the requirements of the specific application. Such options include:

- Discharge hood extensions

- Electrical reset features

- Positioning options of the control panel and hood direction

- Support platforms

It is very important to consider the location and positioning of the discharge hood of the abort gate. The direction of exhaust should not point at areas where people could be present or where structures or materials exist which might catch fire.

Abort Gates are large and heavy so manually resetting the damper blade after an activation is a difficult task with the larger units. For this reason, an electrical reset feature is available. A linear actuator pushes the damper blade back into place allowing the gate to be re-armed. Electrical resets are permitted as long as manual interaction at the gate location is required to reset the gate. Automatic or remote resets are prohibited.

Different system designs are possible for the use of the gates. For further information on the applications for Abort Gates, see NFPA Standards 664 and 654.

WHAT WE DO

SPARK DETECTION & SUPPRESSION SYSTEM

MINIFOG WATER MIST SYSTEM

COMPONENTS

MXONE

HOW CAN WE HELP

Contact our support team for project inquiries, technical questions and service.